Protocol

CADCAM IMPLANT LEVEL

Why choose the CADCAM IMPLANT LEVEL Protocol?

This protocol has been designed to solve the most common difficulties faced by laboratories in direct-to-implant rehabilitations, such as lack of fit, the need for subsequent corrections or uncertainty in the clinical-laboratory relationship.

What do you need?

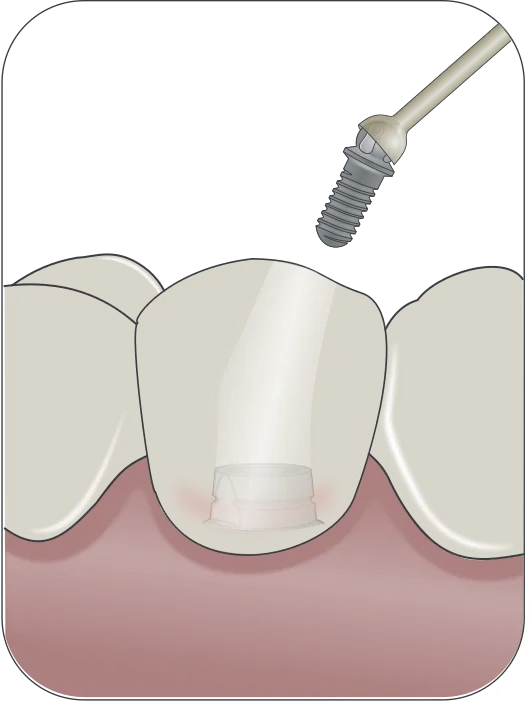

- Screw BHS30

- Screwdriver BHS30

- Scanbody BHS30 and associated BHS30 library

- T-Tool BHS30

- Materials: Sintered or Machined in Metal

Universal compatibility

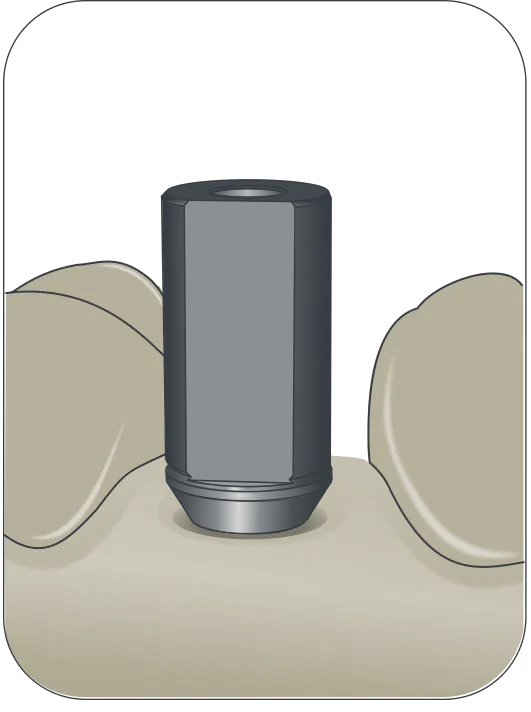

Direct implant fitting

Customized angulation

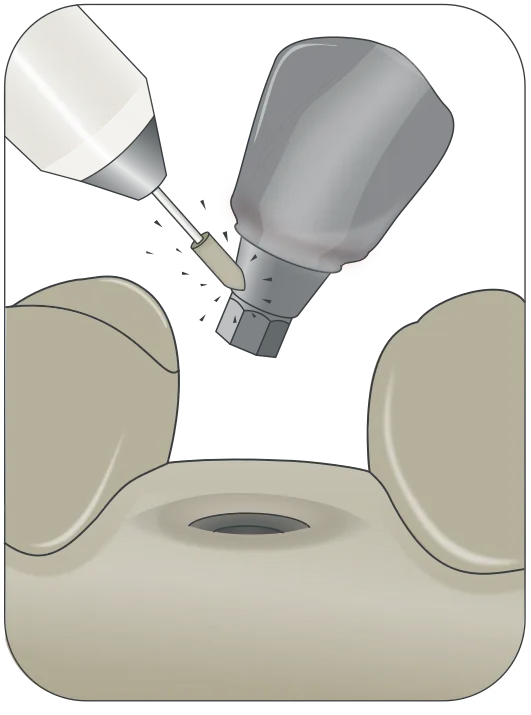

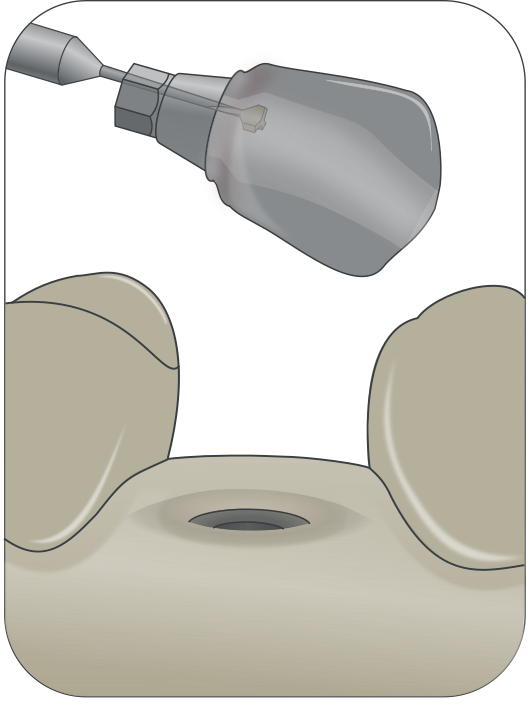

T-Tool BHS30

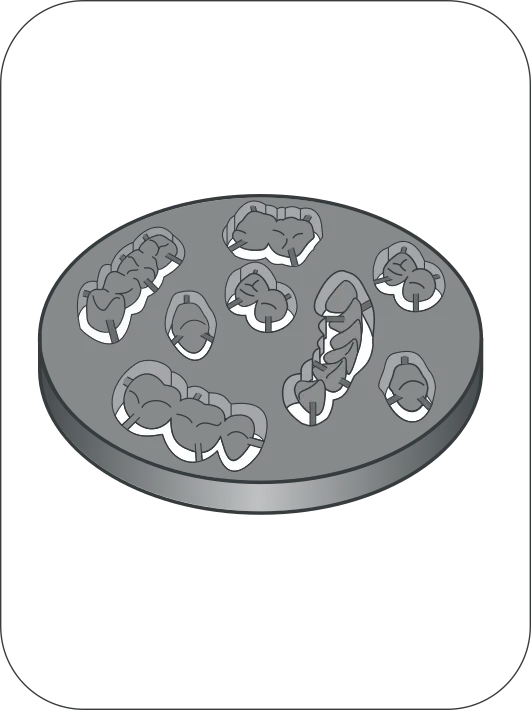

Milling Support

Technical Characteristics of the

CADCAM IMPLANT LEVEL Protocol

CLINIC

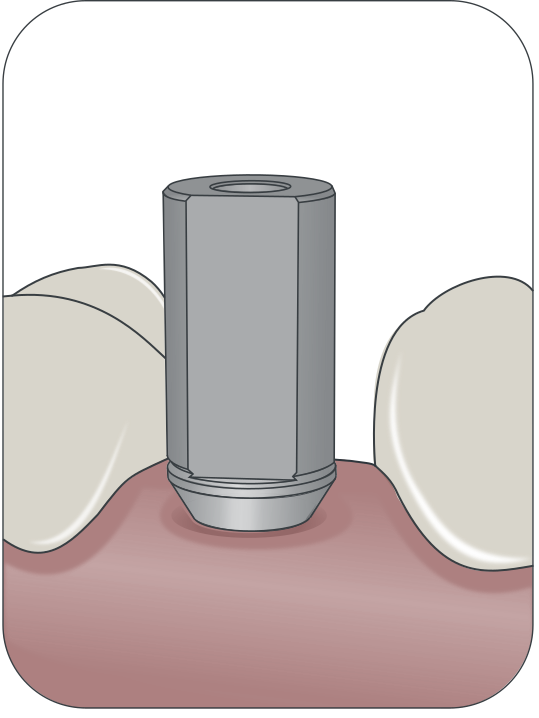

Placement of the Scanbody BHS30 on the patient’s implants and intraoral scanning. Sending the .stl file to the laboratory.

Or scanning in the laboratory on the analogues of the model.

Or scanning in the laboratory on the analogues of the model.

LAB_CAD

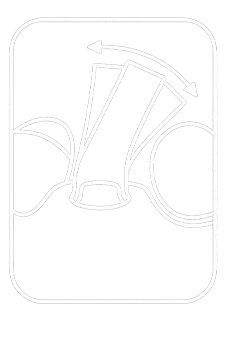

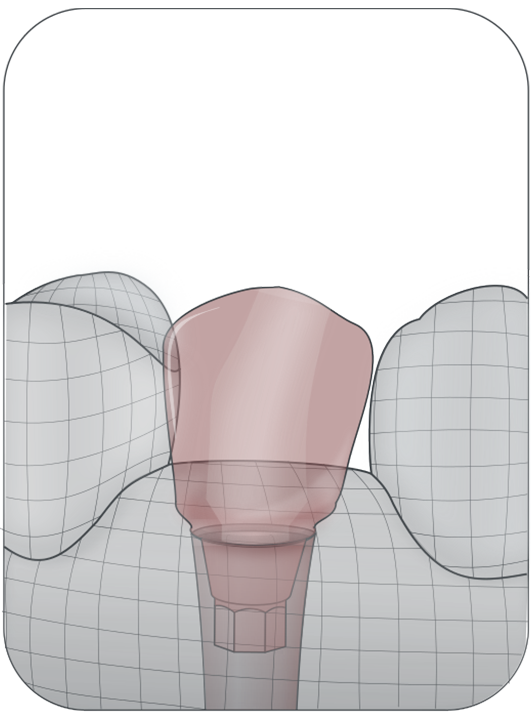

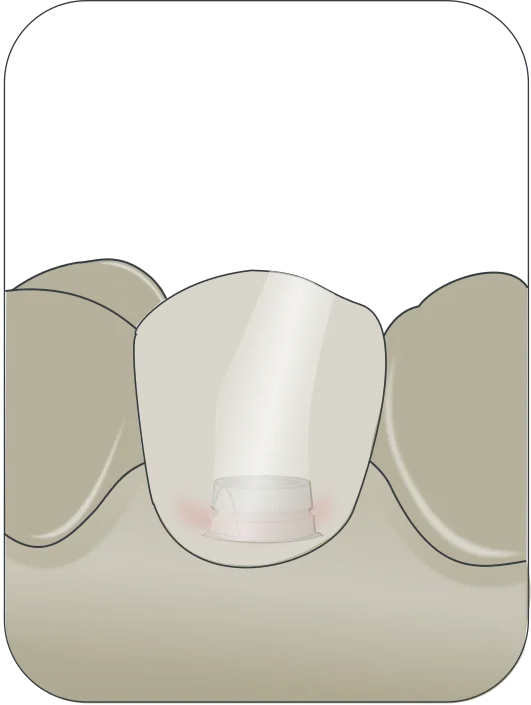

Design of the Direct to Implant framework from the .stl file with the BHS30 library and selection of the desired angulation for the screw access channels, according to the severity of the case.

LAB_CAM

Frame fabrication. T-Tool BHS30 available for perfect fit and finish of the BHS30 screw seating platform.

Consult software and T-Tool compatibility through our Milling Support service.

LAB

Adjustment of the structure on analogs until passivity is obtained on the model.

CLINIC

Metal test, in case of multiple structures, to confirm the fit on the patient’s implants and their actual relationship in the mouth.

LAB

Final adjustments to the structure, if necessary, ceramic loading and finishing.

CLINIC

Placement of the prosthesis for the patient.

More information

Contact an expert

Complete the form below and one of our specialists will contact you as soon as possible.

Visit our online store

Access a detailed selection of components, tools and solutions designed to optimize your workflow.

Discover all the protocols of

Ball Head Technology®.

CADCAM

MULTIUNIT All-on-X

Specialized solution for multiple implant restorations.

Exact fit and time reduction in the design and fabrication process.

Exact fit and time reduction in the design and fabrication process.

Read more