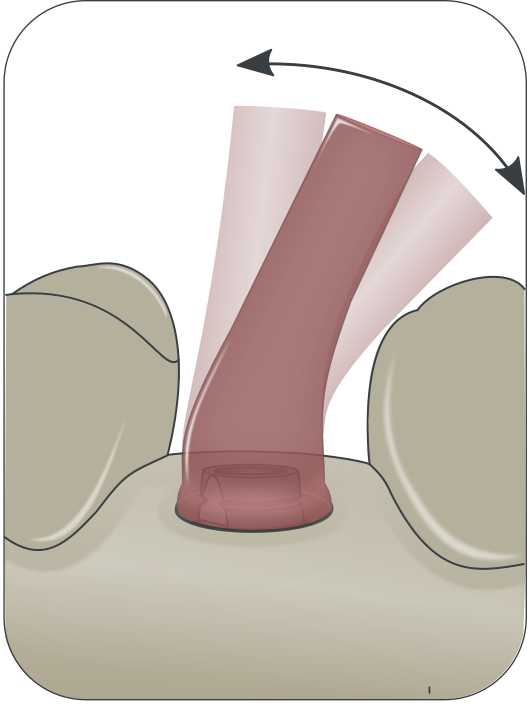

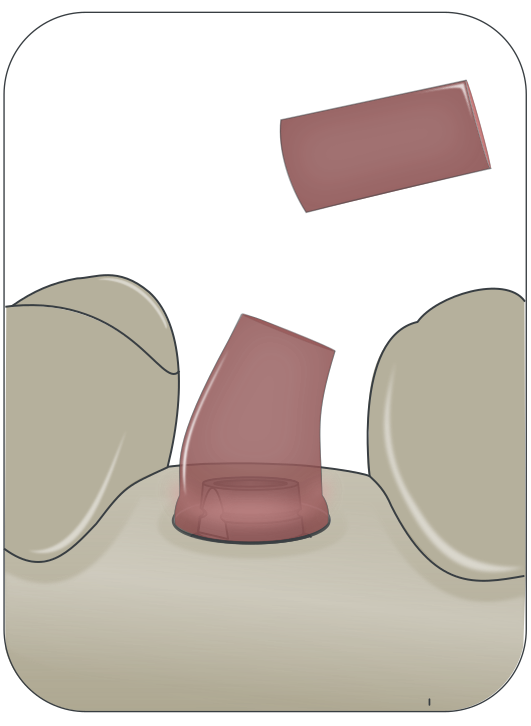

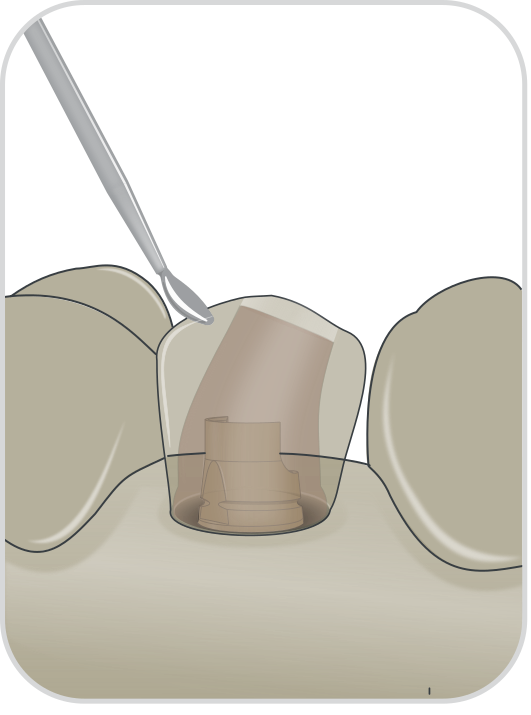

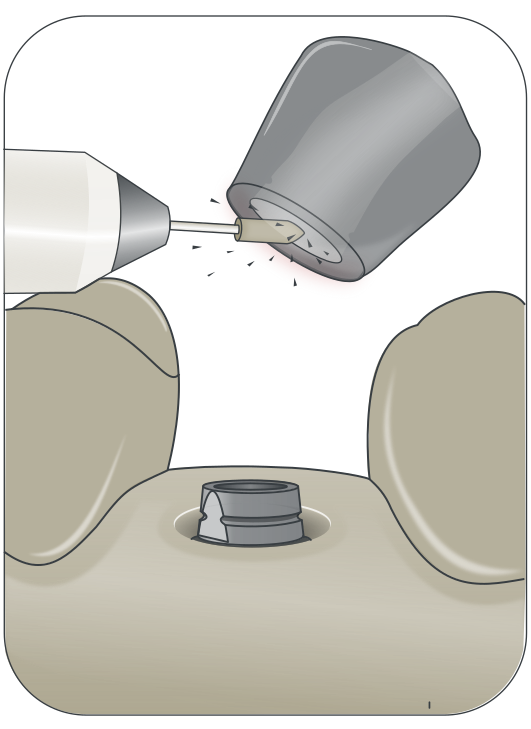

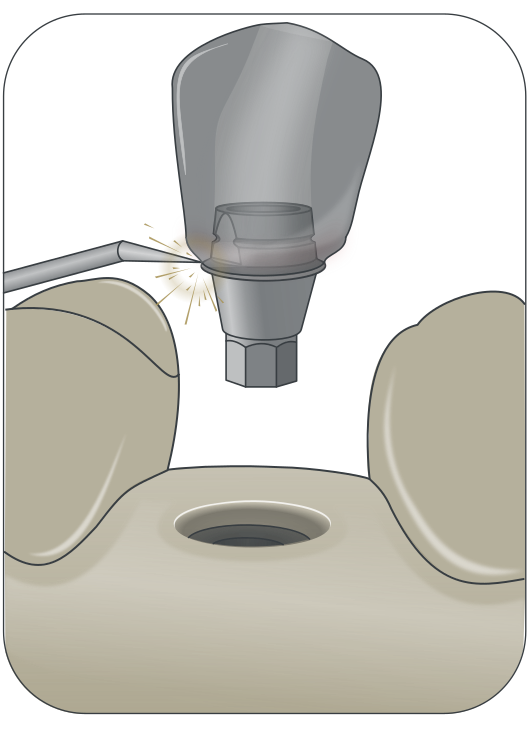

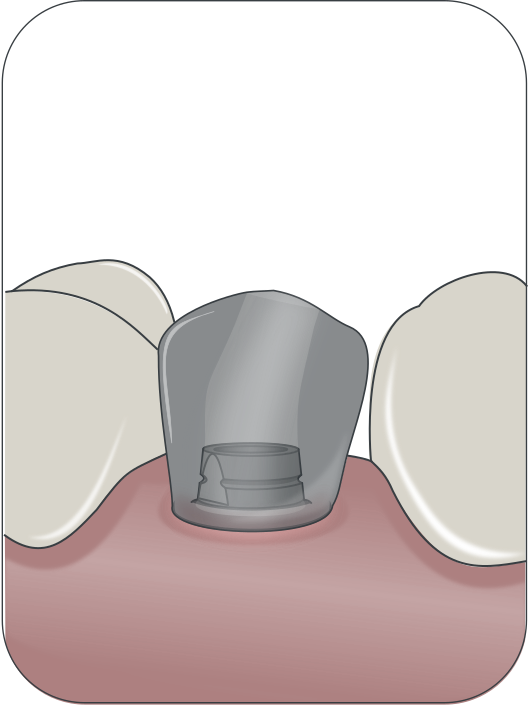

WELDCAST® is Ball Head Technology®’s hybrid solution that combines the advantages of casting with the structural precision of a bolted metal base (CrCo). This protocol is ideal for cases where stability, versatility and verified passive fit are required. It is a safe alternative to full milling, especially useful in multiple rehabilitations, as it allows for clinical corrections prior to final finishing.

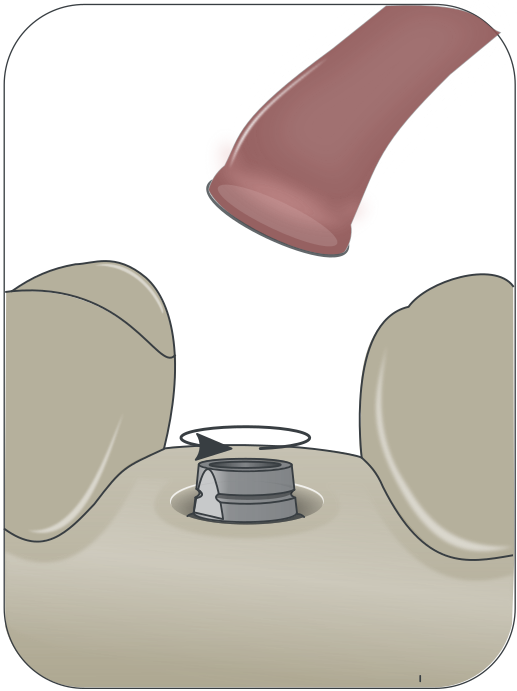

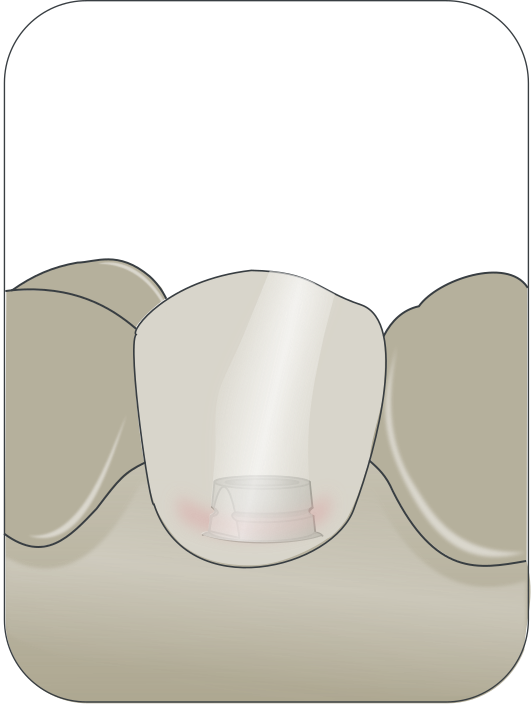

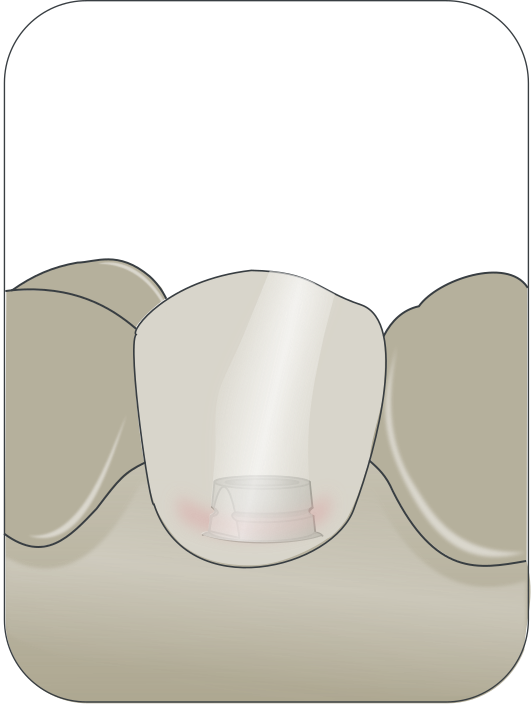

Placement of the prosthesis for the patient.

More information

Complete the form below and one of our specialists will contact you as soon as possible.