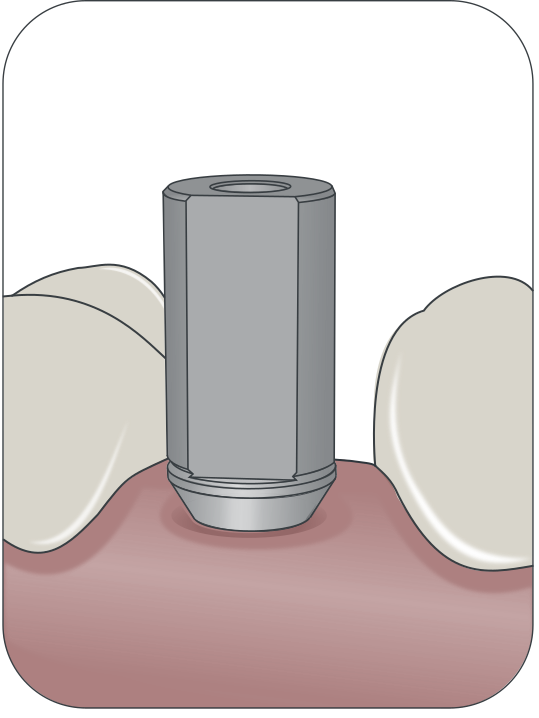

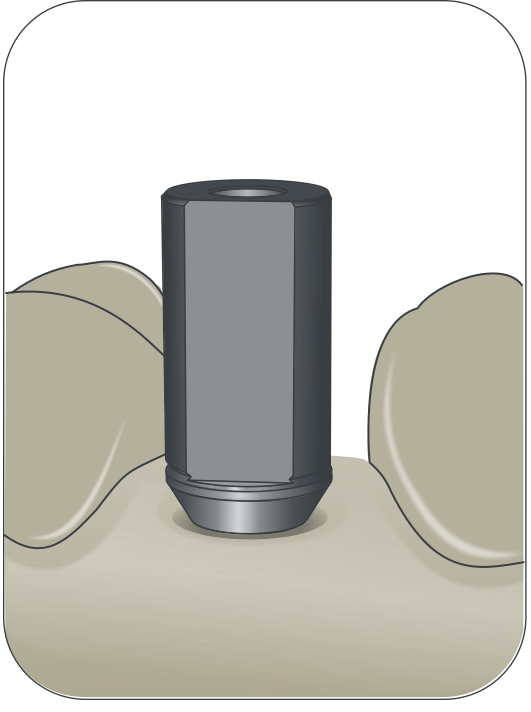

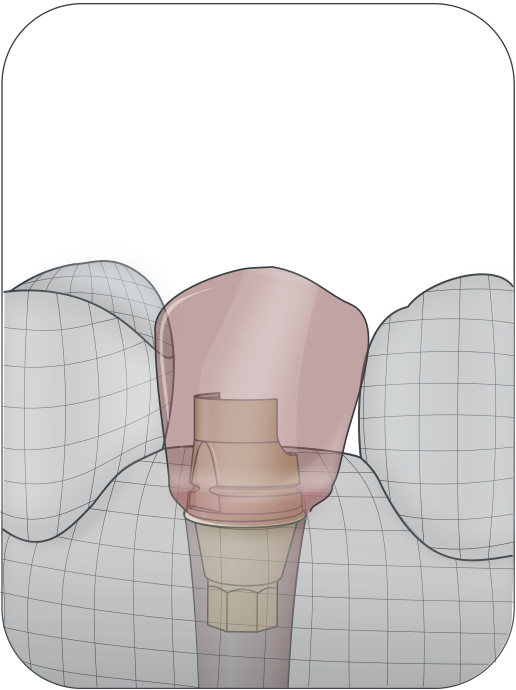

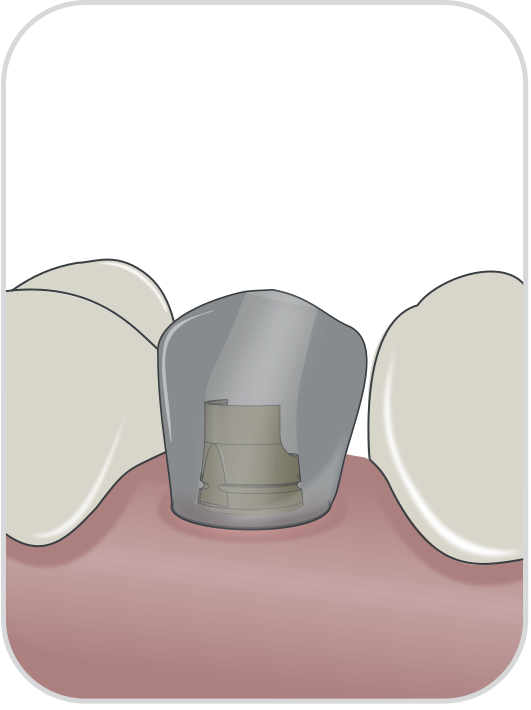

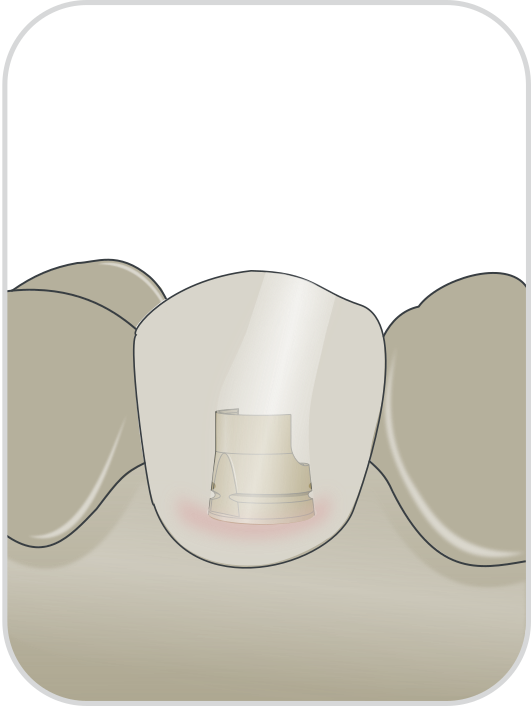

The CADCAM ABUTMENT LEVEL protocol is designed to offer a reliable and flexible solution for cement-retained structures on abutments. It is ideal for cases where it is necessary to work with intermediate components, such as Ti or CrCo bases, ensuring compatibility with different clinical techniques and esthetic needs. It allows maintaining passivity, optimizing laboratory work and facilitating clinical adaptation, even when in-mouth validation or additional customization is required.

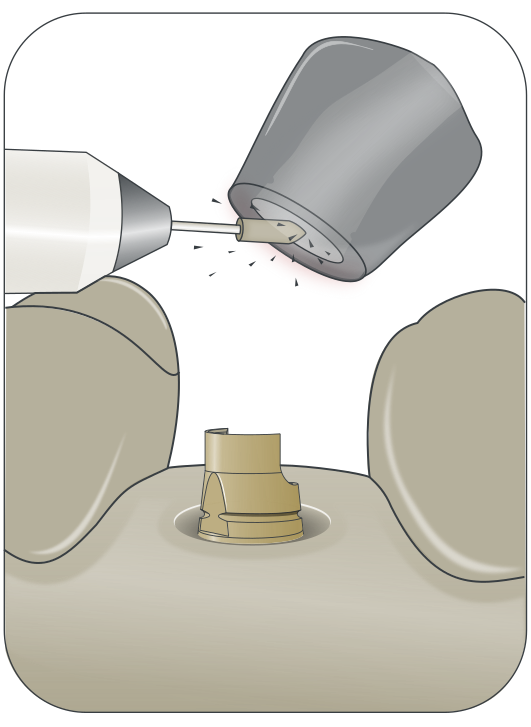

Controlled cementing

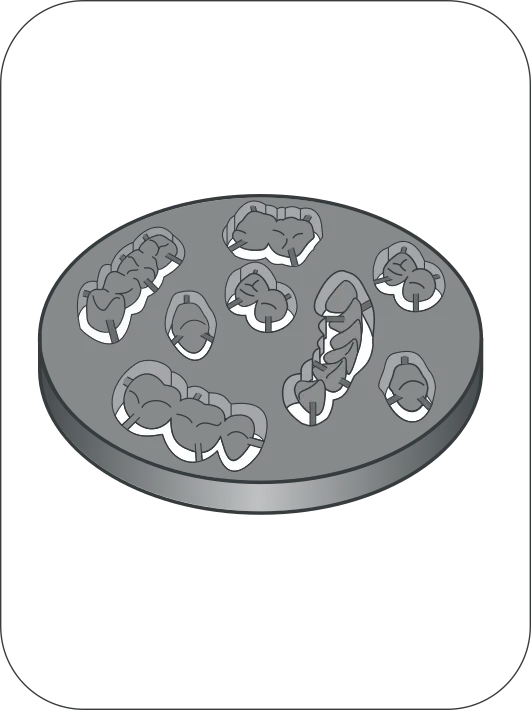

Design of the structure on Ti Base from the .stl file with the BHS30 library and selection of the desired angulation for the screw access channels, according to the severity of the case.

More information

Complete the form below and one of our specialists will contact you as soon as possible.