BHS30 / Screw&driver connection

BHS30 SOLUTION, developed and patented since 2008.

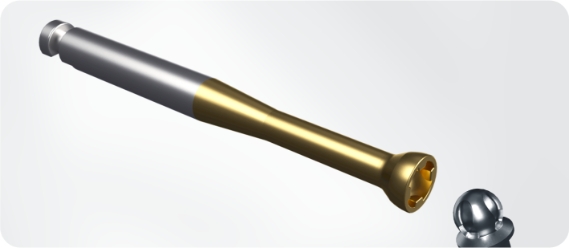

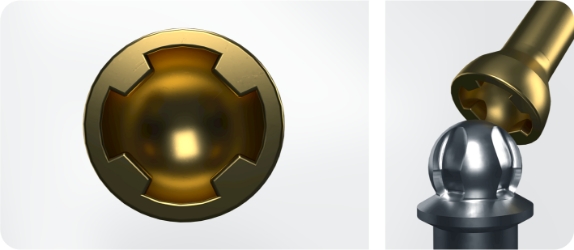

Ball Head System® opens infinite possibilities in dental prosthetic design providing an exceptional mechanical performance, since its exclusive design offers the highest torsion resistance in the market (up to 90 Ncm), always guaranteeing an optimal solution to each implant restoration. The efficient design of the screw and driver, with an angulation capacity of 30º, improves and simplifies prosthetic tasks contributing freedom and accessibility in design.

BHS30 is compatible with direct casting, overcasting, CadCam milling and sintering and has been adapted to the most common implant systems in the market.

ADVANTAGES

- Aesthetic and functional guarantee in your restoration works.

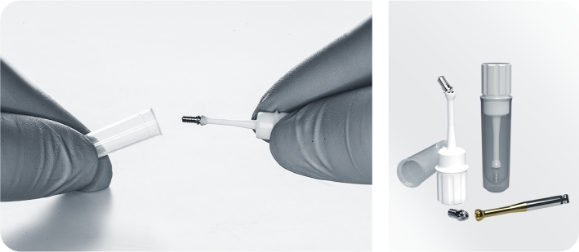

- Hygiene and safety thanks to its handler and individual cap.

- Major comfort and wellbeing for odontologists, lab technicians and patients.

- Higher productivity and profitability, due to savings in materials and time.

BHS30 SCREWDRIVER

BHS30 screwdriver is designed for an optimal coupling with the screw to guarantee the integrity of its head. It allows correcting up to 30º deviations with a 100% efficient torque transmission and offers an astonishing torsion resistance, averaging 90 Ncm in any range of angulation, to provide satisfaction to the most demanding professionals.

Why choose BHS30?

ACCESIBILITY, PROFITABILITY AND EFFICIENCY

BHS30 solution presents the highest angulation capacity in the market and allows correcting the entry of the screw access channel with great simplicity to implants in unfavorable positions. The system is designed to improve aesthetics and functionality of screw-retained prosthesis with an important time and cost reduction in their production.

HYGIENE AND SAFETY

BHS30 connection maintains its kinematic and torsion resistance guarantees even subject to its maximum angulation capacity, ensuring an optimal prosthetic retention. In addition, BHS30 Screw is presented in an individual handler of exclusive design, which allows screw insertion in the patient’s mouth without the need of contact with hands, providing the user an easier manipulation and greater safety.

VISUAL RECOGNITION AND EXCLUSIVITY

The excusive geometry of the BHS30 screw head allows a quick visual identification inside the transocclusal channels and avoids the use of non-compatible tools which may harm the screw and block its removal.

The system has an international exclusivity that guarantees a production under the highest quality standards, as well as the outmost rigor in all supporting technical and scientific documentation.

BHS30, your solution to the problem of screw head stripping during dental prosthesis fixation.