Tech / BHS30 Study Cases / SUBSTITUTION OF ANGLED TO STRAIGHT MULTI-UNIT AND ANGULAR CORRECTION

Case Study 1

SUBSTITUTION OF ANGLED TO STRAIGHT MULTI-UNIT AND ANGULAR CORRECTION

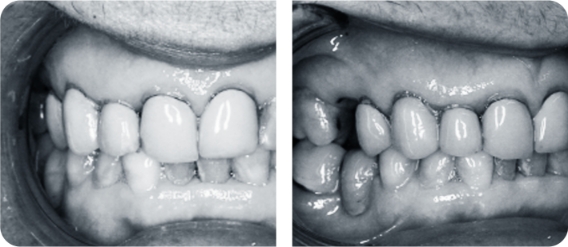

Patient presenting an anterior fix prosthesis, cemented to stumps on natural teeth, that has been fractured causing mobility and instability of the prosthesis. Patient needs a solution which helps improving the aesthetic of his smile.

The initial option is to go for a treatment based on extraction of the prosthesis and harmed teeth and insertion of four implants in positions 22, 21, 12 and 14, correcting emergence profile with conical transepithelial abutments with 17 degrees angulation.

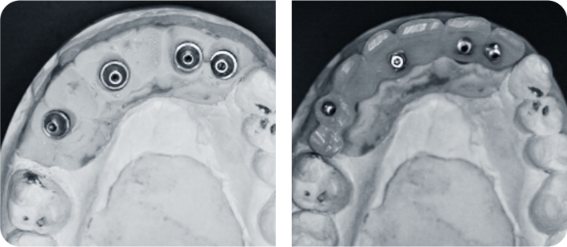

Subsequently, gum reabsorption uncovers the metallic shoulder on one of the pillars and it is determined to substitute them by Straight Multiunit Abutments, bridging vestibular emergence with BHS30 Screws on 20 degrees Angled Castable Cylinders.

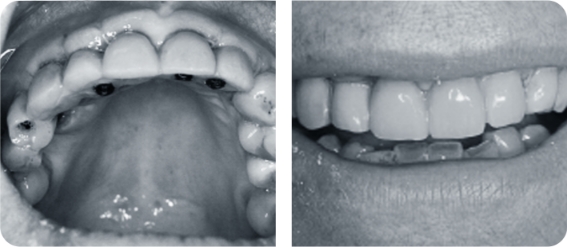

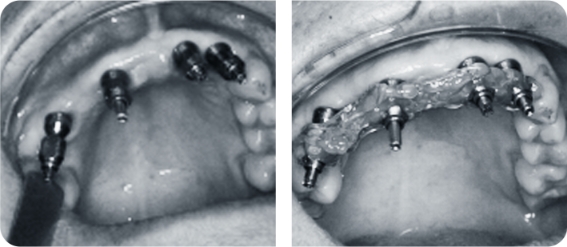

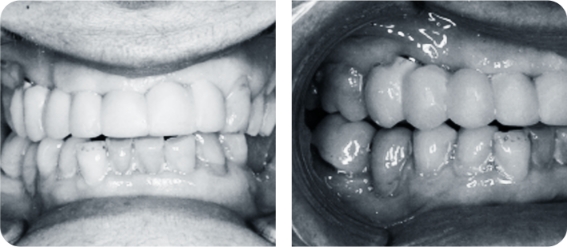

a. Initial situation of the case after diagnosis, where deterioration of the previous cemented prosthesis is observed.

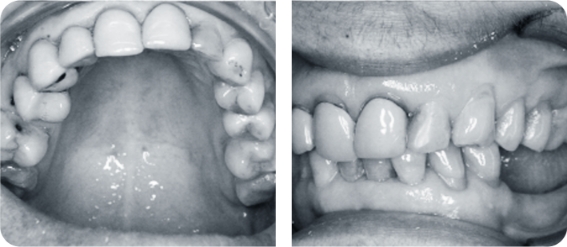

b. After treatment plan is designed, an acrylic temporary structure is made by the lab for screw-retained immediate loading on four implants. The vestibular emergence profile is corrected by 17 degrees angled Multiunit Abutments.

c. After removal of the damaged structure and natural teeth, implants are inserted and immediate load is performed, with satisfactory aesthetic results.

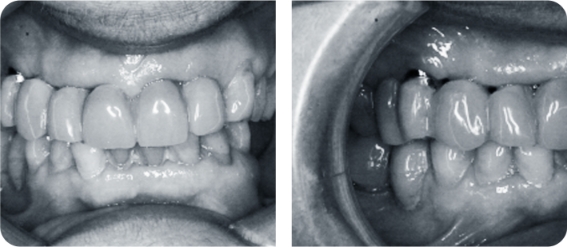

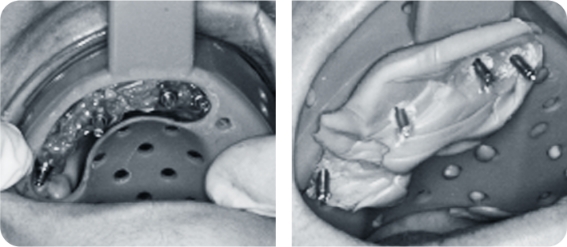

d. 8 months later, and due to soft tissue reabsorption, the shoulder of MU transepithelial in position 14 becomes exposed.

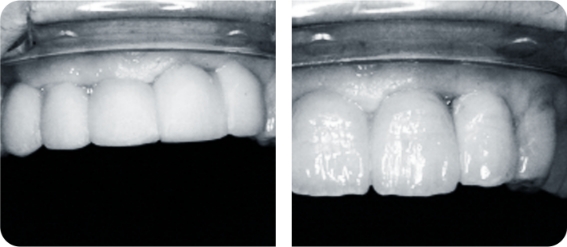

e. Angled Multiunit abutments are replaced by Straight ones, with only 1mm shoulder, to bring down the prosthesis profile.

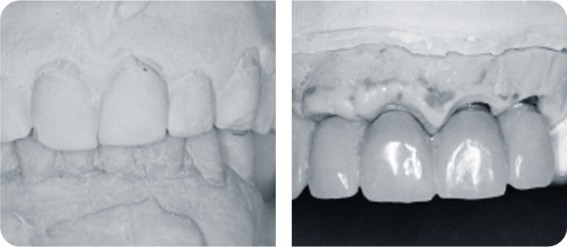

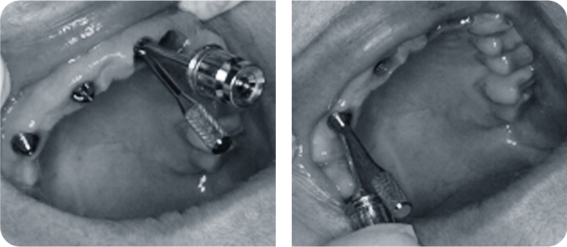

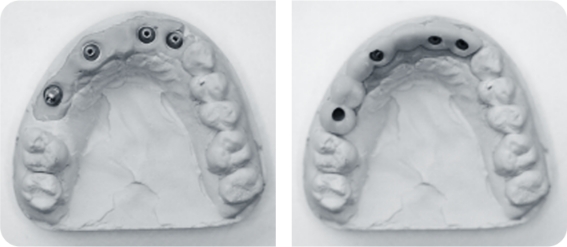

f. Open tray impression is taken to prepare the model. Impression transfers indicate the confronted emergences.

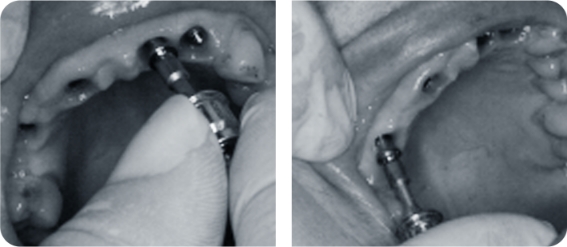

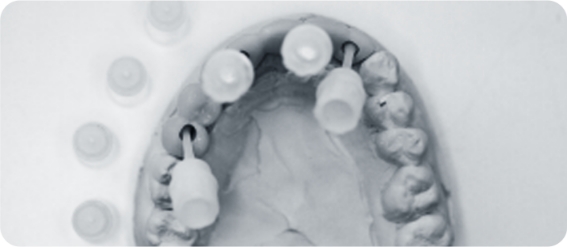

g. Once Straight Multiunits have been incorporated to the model, restoration is manufactured by Direct Casting on Angled Cylinders at 20o, to be fixed to the Multiunit pillars with compatible BHS30 screws.

h. After fitting of the structure is confirmed, ceramic finishing is glazed and the prosthesis is fixed in mouth.